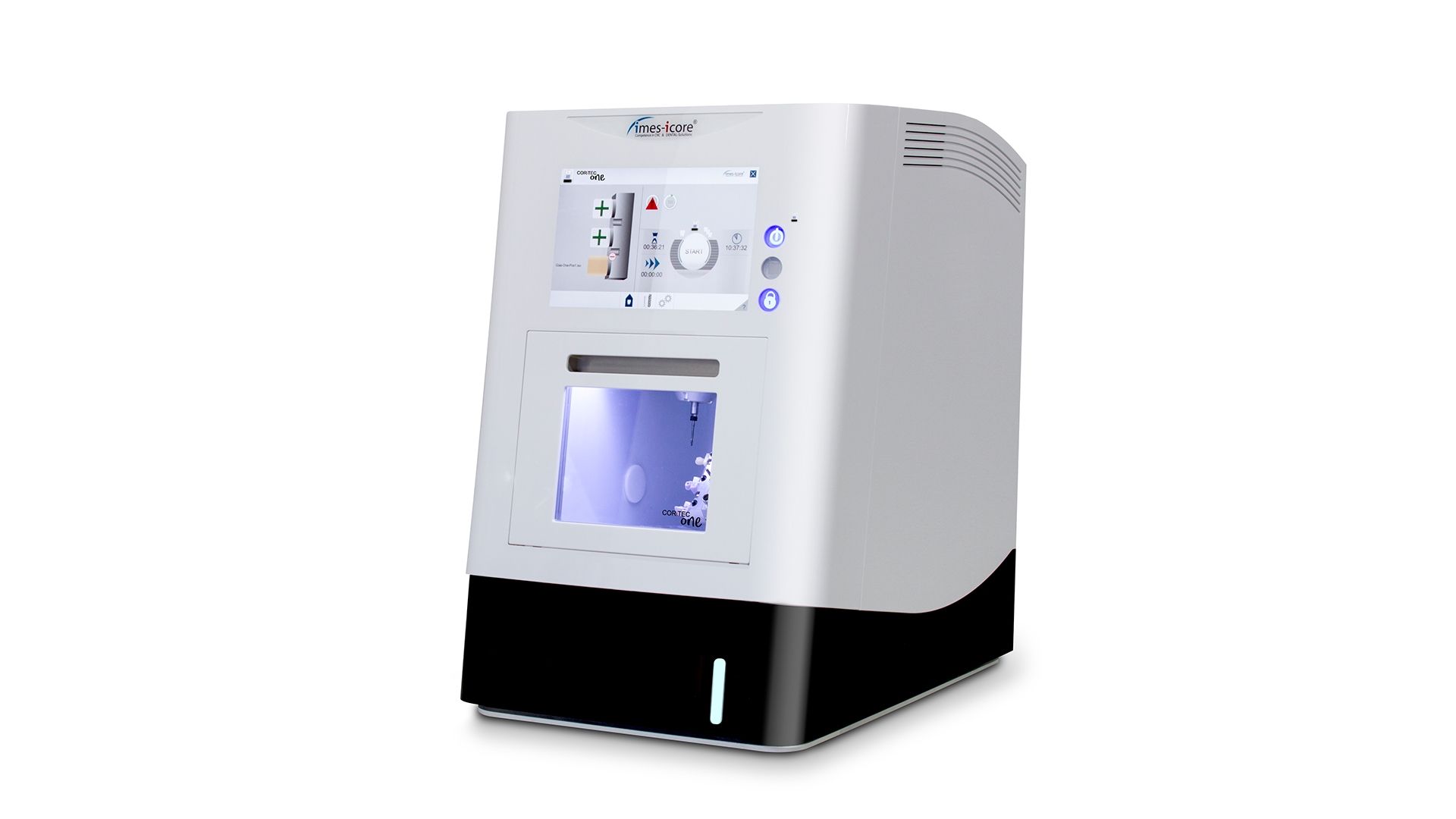

CORITEC ONE

The intelligent Practice Lab Solution 2.0

The new CORiTEC one machine system is suited perfectly for processing any common CAD/CAM blocks up to a size of 65mm x 40mm x 20mm (maxi blocks). Off ering the new and extremely robust axis kinematics, the machine is also able to machine premilled abutments. The high-quality cast aluminum construction facilitates high stability while maintaining the smallest of footprints. Machine operation is user-friendly via the large touchscreen display with its integrated high-performance PC, no additional computer system required. The 3-fold block holder and 6 tool positions with sister (twin) tool function make economic, safe and fast processing possible with the highest possible quality output.

The machine is ideally suited for practice labs, combined with an intra-oral or desktop scanner. For laboratories or milling centers it may be an excellent complementary system for specialized applications like glass ceramics and premilled abutments.

Technical highlights

- a new type of closed mono-block cast body

- optimized touch software operation

- optimized axle kinematics

- high dynamics, precision and speed

- outstanding price-performance ratio

- processing of all commonly used material

blocks, as well as premilled abutments - multi-adapter for up to three blocks or maxi-blocks

(65mm x 40mm x 20mm) - highest degree of stability and precision

- fully integrated wet and dry processing

- automated 6-fold tool changer

- tool runtime monitoring / breakage monitoring

/ tool management / job management - integrated control PC with 10” touchscreen for

smart graphical operation - only low-pressure compressed air needed (2 bar)

- innovative cooling / fi ltering system for easy handling

- fully enclosed wet cell with larger genuine glass pane

- integrated CNC and CAM module

- modern, high-quality and ergonomic machine-design

- efficient milling spindle with 80,000 rpm

Technical Specifications

| Number of axles and machining type | 4-axis simultaneous machining |

| Max. tilt angle of the rotary axis | 360° processing possible |

| Wet and dry processing | Fully integrated |

| Maximum speed / Pmax~ | 80,000 rpm / 0.4 kW |

| Axle drives | Microstep motors |

| Tool fitting | 3 mm shaft |

| Tool changer | 6-fold |

| Workpiece changer | Manual 3-way adapter |

| Weight | 65 kg |

| Width x depth x height | 380x495x600 mm |

| Supply voltage / frequency / power | 100V-240 V/50/60 Hz/800 W |

| Compressed air supply | 2 bar |

| Materials | Premilled abutments, zirconium dioxide, aluminum oxide, PMMA, plastics, composites, wax, glass ceramic, hybrid ceramics |

| Compatibility | CAD/CAM blocks (1-way and 3-way adapter), maxi blocks (65mm x 40mm x 20mm) nt-trading pre-milled abutments, Medentika PreFace® abutments |

Connect with MAC

For any information on Coritec One please do not hesitate to contact us via email – info@mac-ims.com.