CORITEC 350I PRO / LOADER PRO

CORITEC 350I PRO- DENTAL MILLING MACHINE

The professional solution for highest demands!

The developed of the CORiTEC 350i PRO was a completely new machine concept for us. The one-piece machine frame made of polymer concrete provides maximum stability for vibration-free processing. The high-defi nition, dynamic servo motors with absolute measuring systems increase processing speed by up to 20% while maintaining optimum precision.

The developed of the CORiTEC 350i PRO was a completely new machine concept for us. The one-piece machine frame made of polymer concrete provides maximum stability for vibration-free processing. The high-defi nition, dynamic servo motors with absolute measuring systems increase processing speed by up to 20% while maintaining optimum precision.

This makes the CORiTEC 350i PRO suitable for the highest demands of a dental lab or milling center in a very compact design. The CORiTEC 350i PRO is able to process any CAD/CAM materials. The machine’s precision also allows the processing of highly complex restorations such as one-piece implant retained constructions. The standard blank depot makes it possible to process restorations using the 5-axis process with tilt angles of up to 30 degrees. The optional zero point clamping system allows the CORiTEC 350i to easily change the blank Of the complete blank holder by the push of a button. In addition, the zero point clamping system can be used in a variety of diff erent ways and Adapter systems, e.g. The 15-time premilled Abutments Adaper or the Baltic Denture System. The CORiTEC 350i Loader PRO is also equipped with a fully automatic blank changer (for up to 12 blanks).

Technical Highlight

- revolutionary base structure of polymer concrete (PRO)

- 5-axis, simultaneous machining

- absolute measuring system in all axes (PRO)

- new, high-dynamic servo drives for up to 20% quicker processing (PRO)

- Integrated wet and dry processing

- zero point clamping system integrated

- processing of all important materials used in the dental industry,

including metalworking - axis tilt angle up to +/-30°

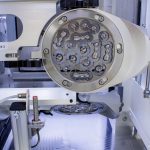

- 20-fold tool changer

- Blank magazine with up to 12 blanks of diff erent materials

- HF spindle with up to 60,000 rpm

- frontal machining of the workpiece possible

(B-axis in 90 degree position)

Retaining bracket system

Technical specifications CORiTEC 350i PRO - dental milling machine

| CORiTEC 350i PRO | CORiTEC 350i Loader PRO | |

| Number of axles and machining type | 5 axes, simultaneous machining | 5-axis simultaneous machining |

| Max. tilt angle of the rotary axis | A-axis +/- 30° / B-axis +/- 25° | A-axis +/- 30° / B-axis +/- 25° |

| Max. axis tilt angle | A-axis: 360° / B-axis: 115° | A-axis: 360° / B-axis: 115° |

| Wet processing | Integrated | Integrated |

| Spindle max. / Pmax~ | 60,000 rpm / 1 kW | 60,000 rpm / 1 kW |

| Axle drives | Servo motors with encoder resolution of 0.5 μm | Servo motors with absolute encoder of 0,15 μm |

| Tool fitting | 6 mm shaft | 6 mm shaft |

| Tool changer | 20-fold with chip protection cover | 20-fold with chip protection cover |

| Workpiece changer | 1-fold manual | 8-fold fully automatic (up to 12-fold optional) |

| Weight | 225 kg | 250 kg |

| width x depth x height | 758x790x857 mm mm | 1058x790x857 mm |

| Mains voltage / frequency / power | 100 V-240 V / 50/60 Hz / 2200 W | 100 V-240 V/50/60 Hz/2200 W |

| Compressed air supply | 6-9 bar constant supply, 60 litres/minute | 6-9 bar constant supply, 60 liters/minute |

| Materials | CoCr/NEM, titanium, zirconium dioxide, aluminium oxide, PMMA, plastics,composites, wax, glass ceramics, hybrid ceramics |

CoCr/NEM, titanium, zirconium dioxide, aluminum oxide, PMMA, plastics, composites, wax, glass ceramics, hybrid ceramics |

| Compatibility | 98 mm/98.5 mm blanks, CAD/CAM blocks, NT-Trading pre-milled abutments, Medentika PreFace®abutments, Lava frames |

98 mm/98.5 mm blanks, CAD/CAM blocks, nt-Trading premilled abutments, Medentika PreFace® abutments, Baltic Denture, Lava Frames |

Connect with MAC

For any information on Coritec 350i Pro/ Loader Pro please do not hesitate to contact us via email – info@mac-ims.com.