CORITEC 350I / LOADER

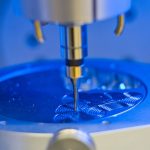

CORITEC 350I - DENTAL MILLING MACHINE

Ultimate all-in-one dental milling machine!

The new CORiTEC 350i processing system is an innovative machine concept, developed to meet any requirements of modern CAD/CAM processing. The processing of all relevant blank materials from CoCr, titanium, zirconium dioxide, plastics, block materials, and new future materials is thus possible with a single machine system, virtually without restrictions.

The modern and optimized machine kinematics, with high free angles of the 5 axes of over 30°, allows milling and grinding as wet and dry processes and with high quality. This makes the system an all-rounder, ideal for demanding labs, to produce all typical applications in your own lab, with high quality, using CAD/CAM technology.

The CORiTEC 350i, with it‘s optional zero point (clamping) system facilitates the quick change of blanks by switching out the entire blank depot with the push of a button. The CORiTEC 350i Loader is equipped with a fully automated 12-fold material changer.

Technical highlights

- 5-axis, simultaneous machining

- Base structure made of steel/aluminum

- Integrated wet and dry processing

- Zero point (clamping) system (optional for CORiTEC 350i)

- processing of all important materials used in the dental industry, including metalworking

- Axis tilt angle up to 30°

- 20-fold tool changer

- HF spindle with up to 60,000 rpm

- Integrated control PC with touch screen

- Servomotors on all axes

- Chip protection of the tool changer

- Frontal machining of the workpiece is possible (B-axis in 90 degree position)

CORITEC 350I LOADER

The automated all-in-one solution!

With the CORiTEC 350i and CORiTEC 350i Loader processing systems, a novel machine concept has been developed which now meets all modern requirements for CAD/CAM processing. The processing of all relevant blank materials from CoCr, titanium, zirconium dioxide, plastics, block materials, and new future materials is thus possible with a single machine system, virtually without restrictions.

The modern and optimized machine kinematics, with high free angles of the 5 axes of over 30°, allows milling and grinding in wet and dry processing in high quality, for almost any application. This makes the system ideal for demanding labs as an all-rounder to produce all typical applications in your own lab, in high quality, using CAD/CAM technology.

In the CORiTEC 350i Loader system, the integrated technology of automated 12-fold material changers is trend-setting; it allows the machine to perform its work at full capacity and round the clock without supervision, in order to, for instance, mill high-volume, time-consuming applications, such as models, splints, or dentures.

Technical specifications CORiTEC 350i - dental milling machine

| CORiTEC 350i | CORiTEC 350i Loader | |

| Number of axles and machining type | 5 axes, simultaneous machining | 5-axis simultaneous machining |

| Max. tilt angle of the rotary axis | A-axis +/- 30° / B-axis +/- 25° | A-axis +/- 30° / B-axis +/- 25° |

| Max. axis tilt angle | A-axis: 360° / B-axis: 115° | A-axis: 360° / B-axis: 115° |

| Wet processing | Integrated | Integrated |

| Spindle max. / Pmax~ | 60,000 rpm / 1 kW | 60,000 rpm / 1 kW |

| Axle drives | Servo motors with encoder resolution of 0.5 μm | Servo motors with absolute encoder of 0,15 μm |

| Tool fitting | 6 mm shaft | 6 mm shaft |

| Tool changer | 20-fold with chip protection cover | 20-fold with chip protection cover |

| Workpiece changer | 1-fold manual | 8-fold fully automatic (up to 12-fold optional) |

| Weight | 225 kg | 250 kg |

| width x depth x height | 1058x790x857 mm | 1058x790x857 mm |

| Mains voltage / frequency / power | 100 V-240 V / 50/60 Hz / 2200 W | 100 V-240 V/50/60 Hz/2200 W |

| Compressed air supply | 6-9 bar constant supply, 60 litres/minute | 6-9 bar constant supply, 60 liters/minute |

| Materials | CoCr/NEM, titanium, zirconium dioxide, aluminium oxide, PMMA, plastics,composites, wax, glass ceramics, hybrid ceramics |

CoCr/NEM, titanium, zirconium dioxide, aluminum oxide, PMMA, plastics, composites, wax, glass ceramics, hybrid ceramics |

| Compatibility | 98 mm/98.5 mm blanks, CAD/CAM blocks, NT-Trading pre-milled abutments, Medentika PreFace®abutments, Lava frames |

98 mm/98.5 mm blanks, CAD/CAM blocks, nt-Trading premilled abutments, Medentika PreFace® abutments, Baltic Denture, Lava Frames |

Connect with MAC

For any information on Coritec 350i/ Loader please do not hesitate to contact us via email - info@mac-ims.com.