CORITEC 350I ROBOT - DENTAL MILLING MACHINE

The fully automatic modular solution for production centers

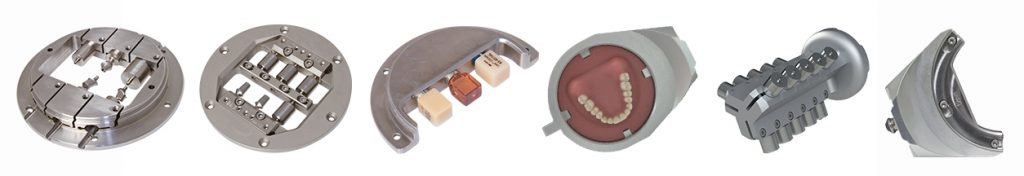

This high-end system for milling centers was built on the basis of the innovative CORiTEC 350i PRO. All installed components are designed for precision, durability and are state-of-the-art: Basic structure of polymer concrete, AC servo drives with absolute measuring systems in all axes, zero point (clamping) system and intelligent central job management. The production line is equipped with a 6-axis handling robot and a large blank magazine, which completes the system into a fully automatic production line for all relevant materials.

The machine design of the “PRO” series is able to master the always accurate, vibration-free and dynamic movement sequences for all demanding and complex materials, so that excellent surface quality and accuracy can be achieved during milling and grinding using wet or dry processes.

Technical Highlight

- fully automatic production line for all materials relevant

to dentistry - robotic handling of machine loading and unloading

- fully automated 24 hour production is possible

- up to 84 dental blanks in the integrated material

storage - loading new blanks and discharging the work during

the production process - expandable up to 5 “CORiTEC 350i PRO“- milling

machines with one robot handler - optional laser cutting and engraving system for labelling

and separating the milled workpieces - job management software for intelligent control of the

production line

Technical Specifications

| Number of axes and machining type | 5-axis simultaneous, laser machining | |

| Max. tilt angle for machining with 98 mm blank | A-axis +/- 30° / B-axis +/- 25° | |

| Wet processing | integrated, several separate loops are possible | |

| Maximum speed / Pmax~ | 60,000 rpm / 1 kW | |

| Axle drives | AC servo motors with high-resolution absolute measuring systems | |

| Tool fi tting | 6 mm shaft | |

| Tool changer (Pro machine model) | 20-fold with chip protection cover | |

| Workpiece changer | 21 / machine model with fully automatic robot handling | |

| Weight | approx. 500 kg (2 machines) to 1250 kg (5 machines) | |

| Width x depth x height | 1600 mm to 4000 mm x 1300 mm x 2000 mm | |

| Supply voltage / frequency / power | 100 V-240 V / 50/60 Hz / 2200 W Pro machine model | |

| Compressed air supply (Pro model) | 6-8 bar constant supply, 60 liters/minute | |

| Materials | CoCr, titanium, zirconium dioxide, aluminum oxide, PMMA, plastics, composites, wax, glass ceramics, hybrid ceramics |

|

| Compatibility | 98 mm/98.5 mm blanks, CAD/CAM blocks, nt-Trading premilled abutments, Medentika PreFace® abutments, Baltic Denture, Lava Frames |

Connect with MAC

For any information on Coritec 350i Robot please do not hesitate to contact us via email - info@mac-ims.com.